Hey there, curious reader! Ever wondered how those precision instruments work their magic? We’re about to dive into the fascinating world of dial calipers, those nifty tools that make precise measurements look like a piece of cake.

In our daily lives, precision measurements often fly under the radar, but they’re everywhere – from the ingredients in your grandma’s secret cake recipe to the critical dimensions of aerospace components. This article will peel back the curtain and reveal the wonders of dial calipers.

Understanding Dial Calipers

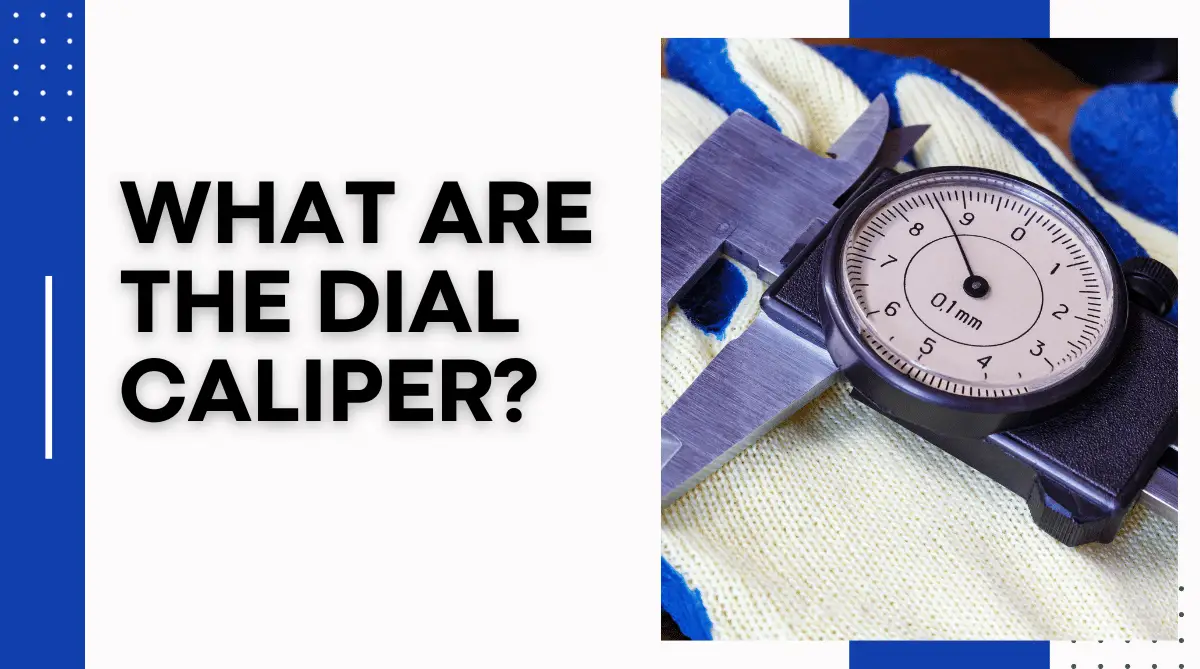

So, let’s kick things off by answering the fundamental question: What are dial calipers? Well, think of them as the Sherlock Holmes of measurement tools. They’re all about precision and solving measurement mysteries.

Dial calipers are handheld devices designed to measure the dimensions of objects with remarkable accuracy. Picture a ruler, but with a supercharged dial that can pinpoint measurements down to a fraction of a millimeter or thousandths of an inch. They come in two main flavors: Vernier dial calipers and Digital dial calipers.

Types of Dial Calipers

Let’s zoom in on these two types to get a better feel for what sets them apart:

Vernier Dial Calipers: These are like the classics, an antique clock that still keeps perfect time. Vernier calipers use a sliding scale alongside the main scale to give you incredibly precise readings. They’re a bit like a treasure map where you align marks to find the hidden treasure – your measurement.

Digital Dial Calipers: Think of these as the high-tech, digital sidekicks. They’ve got a digital display that reads out measurements instantly, like a speedometer telling you exactly how fast you’re going. No need to squint at tiny lines – it’s all right there on the screen.

Anatomy of Dial Calipers

Now, let’s crack open the hood and see what makes these dial calipers tick. Here’s a sneak peek into their inner workings:

Dial Caliper Components: Dial calipers are sleek machines with a few critical parts. The main scale, the sliding jaw, the dial (or digital display), and the depth gauge all work together in harmony. The main scale sets the stage for measurement, the sliding jaw adjusts to fit your object, and the dial or digital display reveals the magic number.

How They Work: It’s a bit like a well-choreographed dance. When you slide the jaws of the caliper over an object, they move in sync, and the dial or digital display spins like a compass needle finding true north. That spinning dial points to the precise measurement, making it easy for you to read. Imagine it as your personal measurement GPS, guiding you to your destination with pinpoint accuracy.

With the basics down, we’re ready to explore how to put these dial calipers to work and unlock their full potential. So, stay tuned for the next section on “How to Use Dial Calipers” – we promise you’ll be measuring like a pro in no time!

Case Study: Precision Engineering with Dial Calipers

Now that we’ve grasped the fundamentals of dial calipers, let’s dive into the real world. Imagine you’re in the bustling world of aerospace manufacturing, where precision is everything. In this case study, we’ll see how dial calipers play a pivotal role.

Real-Life Example 1: Aerospace Component Manufacturing

Picture a massive aircraft hangar, where engineers are crafting intricate components for a state-of-the-art jetliner. These components must fit together with Swiss-watch precision. Dial calipers come to the rescue, ensuring every piece aligns perfectly.

In this example, an engineer uses a dial caliper to measure the dimensions of a critical part. The dial caliper’s precise readings guarantee that the component will integrate seamlessly into the aircraft’s structure. This level of accuracy ensures passenger safety and the aircraft’s overall performance.

Real-Life Example 2: Automotive Brake System Development

Now, let’s shift gears to the world of automotive engineering. When designing a new braking system, every millimeter counts. Imagine you’re in a bustling auto lab where engineers are working on the next-gen brakes. They rely on dial calipers to fine-tune their designs.

In this case study, we’ll focus on the development of brake pads. Engineers use dial calipers to measure the thickness and dimensions of these pads. This precise data helps them optimize braking efficiency and safety. It’s like tuning a musical instrument to produce the perfect note – only here, it’s about creating a braking system that stops on a dime.

Measured Dimensions and Tolerances

Numbers tell a story, and in precision engineering, they do so with utmost clarity. Let’s take a peek at a data table showcasing measurements taken with dial calipers.

| Component | Dimension (mm) | Tolerance (± 0.02 mm) |

| Aerospace Part | 127.35 | 0.02 |

| Brake Pad | 9.88 | 0.01 |

These numbers aren’t just digits; they represent the heartbeat of precision engineering. The dial caliper’s accuracy ensures that these measurements are as reliable as the North Star in the night sky.

Accuracy and Precision: Dial Calipers vs. Other Measurement Tools

So, you might wonder, how does the trusty dial caliper stack up against its measurement cousins? Let’s dissect this by comparing it to vernier and digital calipers.

Comparing Dial Calipers to Vernier Calipers

Think of dial calipers as the classic vinyl record player in a world of modern streaming services. Vernier calipers, like CDs, offer good precision but may require a touch more finesse. Dial calipers, on the other hand, give you a smooth, analog reading, much like the rich sound of a vintage record.

Comparing Dial Calipers to Digital Calipers

Digital calipers are like the latest smartphone, flashy and high-tech. They provide quick digital readings that are easily readable on a screen. However, they might leave you craving the tactile satisfaction of a dial caliper’s smooth glide. It’s akin to choosing between an e-book and a paperback – both have their perks.

Use Cases for Different Measurement Tools

Much like a chef selects the right knife for a specific task, engineers and craftsmen pick their measurement tools wisely. Dial calipers shine when precision is paramount. Vernier calipers come into play when you need a balance between precision and ease of use, while digital calipers are like the Swiss Army knives, versatile for various situations but often more suited for quick readings.

Maintenance and Care for Dial Calipers

Your dial caliper, like a trusty steed, deserves proper care to ensure it serves you faithfully for years to come. Let’s explore how to keep it in prime condition.

Cleaning and Lubrication

Think of your dial caliper as a finely tuned sports car – it needs regular maintenance. Clean it with a soft cloth to remove debris and use a drop of lubricant to keep its parts moving smoothly. Treat it well, and it will repay you with accurate measurements.

Storage and Protection

Storing your dial caliper properly is like tucking it into a cozy bed at night. Keep it in a protective case or pouch to shield it from dust and accidental damage. Avoid tossing it in a toolbox like a forgotten toy; it deserves better.

Periodic Calibration and Inspection

Your dial caliper is a precision instrument, and just like a musical instrument needs tuning, it requires calibration. Periodically check its accuracy with gauge blocks or a master square. If it’s off-key, recalibrate it to maintain its flawless performance.

Common FAQs About Dial Calipers

Got questions about dial calipers? Don’t worry; we’ve got you covered. Let’s address some of the most common queries that may be swirling in your mind.

What is the difference between dial calipers and digital calipers?

Think of it like comparing an old-school analog clock to a digital one. Dial calipers have a traditional dial face, while digital calipers display measurements numerically on an electronic screen. Both do the job, but the choice depends on your preference for classic or modern.

How do I zero my dial calipers?

Zeroing your dial caliper is as simple as setting your watch. Place the jaws together and adjust the dial to read “0.” It’s like resetting your pedometer to start counting your steps from zero.

Can I use dial calipers for both internal and external measurements?

Absolutely! Dial calipers are versatile. They can measure both inside and outside dimensions, making them your go-to tool for various tasks. It’s like having a Swiss Army knife in your toolbox.

What is the maximum measurement range for dial calipers?

The maximum range can vary, but typically it’s around 150mm (6 inches). Beyond that, you might need larger measuring tools, like micrometers or caliper gauges.

How often should I calibrate my dial calipers?

Calibrating your dial calipers depends on how frequently you use them. If you use them daily, a monthly check is a good practice. If they see less action, a quarterly calibration should suffice. It’s like giving your car an oil change based on mileage.

Are there any safety precautions I should follow when using dial calipers?

Safety first! Remember that the jaws of a dial caliper are sharp, so handle them with care to avoid injury. Also, keep the caliper clean to prevent any dirt or debris from affecting its accuracy. Think of it like handling a delicate tool, much like a surgeon’s scalpel.

Conclusion

As we wrap up our journey into the world of dial calipers, remember that precision and accuracy are the cornerstones of countless industries. Dial calipers, with their timeless design and unwavering reliability, continue to play a vital role in ensuring that the products we use daily, from airplanes to automobiles, meet the highest standards of quality and safety.

So, whether you’re an engineer crafting the future of technology or a hobbyist pursuing perfection in your projects, dial calipers are your trusty companions in the pursuit of precision. Keep them clean, calibrated, and close at hand, and they’ll reward you with measurements as exact as a masterful piece of art. Happy measuring!