Vernier calipers are precision measuring instruments that have become an indispensable tool in various industries and applications. These remarkable devices offer a level of accuracy and detail that is unmatched by conventional measuring tools. Whether it’s in engineering, manufacturing, scientific research, or everyday tasks, vernier calipers play a vital role in ensuring precise measurements.

Importance of Vernier Calipers:

The importance of mastering the use of vernier calipers cannot be overstated. In today’s world, where precision is the key to success, these instruments pave the way for accurate measurements. Engineers rely on vernier calipers to design intricate components with tight tolerances, ensuring the seamless functioning of machines and structures. Manufacturers use them to fabricate products that meet stringent quality standards. Scientific researchers depend on vernier calipers to gather precise data for their experiments. Even in everyday scenarios, vernier calipers prove handy for tasks like measuring objects and ensuring proper fits.

By the end of this guide, you will have gained a profound understanding of vernier calipers and be equipped with the knowledge to achieve accurate results in your measurements.

Definition and Historical Background of Vernier Calipers

Vernier calipers are precision measuring instruments used to measure the dimensions of various objects with high accuracy. They consist of a main scale and a sliding vernier scale, which allows for more precise readings than traditional measuring tools. The invention of the vernier scale is credited to Pierre Vernier, a French mathematician and instrument maker, who introduced this ingenious measuring technique in the early 17th century.

Components of Vernier Calipers

To comprehend the functioning of vernier calipers, it is essential to familiarize ourselves with its key components:

a) Main Scale: The main scale is the longer, fixed scale on the body of the caliper. It is graduated with measurement units, such as millimeters or inches, depending on the caliper’s design.

b) Vernier Scale: The vernier scale is a shorter scale that slides alongside the main scale. It contains divisions that are slightly smaller than those on the main scale. The vernier scale is responsible for providing the fractional part of the measurement, enhancing the precision of readings.

c) Upper Jaw: The upper jaw of the vernier caliper is used to secure the object being measured firmly. It holds the object in place during the measurement process.

d) Lower Jaw: The lower jaw, also known as the depth rod or depth probe, extends from the bottom of the vernier caliper. It is used to measure the depth of holes and other recessed features in objects.

Distinction from Other Measuring Instruments

Vernier calipers possess unique features that set them apart from other measuring instruments like rulers or tape measures. Unlike rulers that have only one scale and are suitable for straightforward measurements, vernier calipers offer greater accuracy and versatility. The ability to measure both inside and outside dimensions, as well as depths, makes vernier calipers indispensable tools in various industries.

One notable feature that distinguishes vernier calipers from digital calipers is the ease of reading the measurements. While digital calipers provide readings on an electronic display, vernier calipers require users to visually align the scales to determine the measurement accurately. This method enhances the user’s spatial awareness and measurement skills, which are valuable traits in fields where precision is paramount.

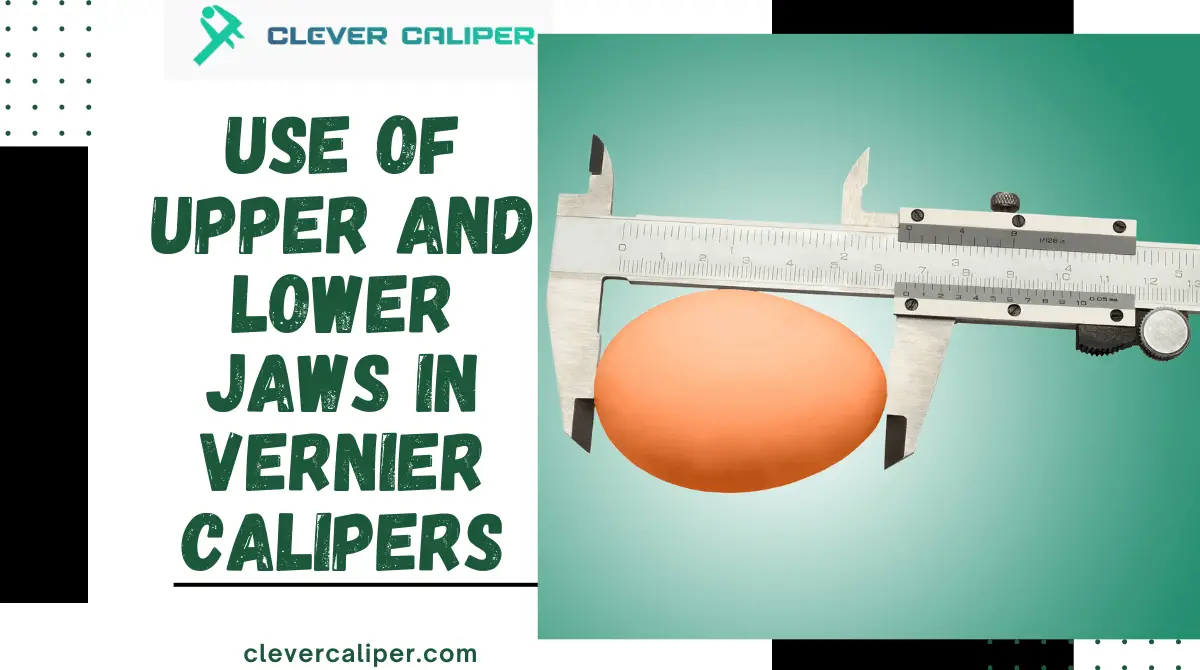

Importance of Upper and Lower Jaws

The proper utilization of the upper and lower jaws in vernier calipers is vital for achieving accurate and reliable measurements. In this section, we will explore the significance of each jaw and how they contribute to the overall precision of the instrument.

The Function of the Upper Jaw

The upper jaw of the vernier caliper serves the crucial role of firmly holding the object that requires measurement. When taking a measurement, the object is placed between the upper and lower jaws, and the user gently tightens the caliper to secure the object in place. The firm grip ensures that the object does not move or shift during the measurement process, preventing errors caused by instability.

The proper alignment of the upper jaw with the main scale is essential for accurate readings. Any misalignment can lead to incorrect measurements, which highlights the significance of proper handling and attention to detail while using vernier calipers.

The Role of the Lower Jaw

The lower jaw, or depth probe, plays a crucial role in measuring the depth of holes, slots, and other recessed features in objects. It extends from the bottom of the vernier caliper and can be adjusted to reach the bottom of a cavity for precise depth measurements.

When measuring depths, the user aligns the lower jaw with the bottom of the cavity and gently closes the caliper until the depth probe makes contact with the surface. The reading obtained from the main scale and the vernier scale provides the accurate depth measurement, making it a valuable feature for applications that require precise depth analysis.

Significance of Using Both Jaws Properly

The proper use of both the upper and lower jaws is essential for achieving error-free measurements with vernier calipers. Using only one jaw while neglecting the other can lead to inaccurate readings and compromise the precision of the measurements.

By utilizing both jaws effectively, the user ensures that the object is held securely, minimizing any potential movement that could affect the measurement. Additionally, combining the main scale and vernier scale readings obtained from both jaws provides a comprehensive and accurate measurement of the object’s dimensions.

Mastering the art of using both jaws in tandem not only enhances measurement accuracy but also showcases the user’s proficiency in handling vernier calipers, reflecting the precision required in professional settings.

Step-by-Step Guide to Using Vernier Calipers

Using vernier calipers may seem daunting at first, but with practice and understanding of its components, you can quickly become proficient in taking accurate measurements. Follow these step-by-step instructions to master the art of using vernier calipers:

Step 1: Understanding the Main Scale and Vernier Scale Readings

Before using the vernier calipers, familiarize yourself with the main scale and the vernier scale readings. The main scale is the larger, fixed scale on the caliper’s body, while the vernier scale is the sliding scale attached to the main scale. Each scale represents different units of measurements, such as millimeters or inches.

Step 2: Closing the Jaws and Taking Initial Measurements

Start by closing the jaws of the vernier calipers completely. This ensures that there is no slack and the caliper is ready for accurate measurements. Place the object you want to measure between the jaws, ensuring it sits flat and flush with the jaws’ inner surfaces.

Step 3: Sliding the Caliper to Fit the Object Accurately

Carefully slide the vernier calipers until the object is snugly held between the jaws. Make sure the caliper is aligned perpendicular to the object’s surface for precise measurements. Avoid applying excessive force, as it may deform the object or affect the accuracy of the reading.

Step 4: Reading the Measurement from the Vernier Scale

To read the measurement, first, identify the whole number measurement from the main scale that aligns with the left end of the vernier scale. Next, look for the vernier scale mark that precisely aligns with any mark on the main scale. The aligned mark on the vernier scale provides the decimal or fractional part of the measurement.

Step 5: Making Precise Measurements with Zero Error

Practice is essential to achieve accurate measurements with zero error. Avoid parallax error, which occurs when the eye is not directly perpendicular to the measurement marks. Always ensure that your eye level is aligned with the markings for precise readings. Take multiple measurements to cross-verify the accuracy and consistency of your results.

Practical Applications

Vernier calipers find extensive use in various industries and fields due to their unparalleled accuracy. Some of the practical applications include:

Engineering and Manufacturing: Vernier calipers are indispensable tools in engineering and manufacturing processes. They are used to measure components’ dimensions, ensuring precise fits and alignments in machinery and structures. Engineers rely on vernier calipers for quality control, ensuring products meet stringent standards.

Scientific Research: In scientific research, accuracy is crucial. Vernier calipers aid scientists in measuring small objects and experimental samples with utmost precision. From analyzing biological specimens to evaluating the dimensions of microscopic structures, these calipers play a vital role in advancing scientific knowledge.

Architecture and Construction: Architects and builders use vernier calipers to measure various aspects of construction projects accurately. From wall thickness to window dimensions, every detail matters in creating functional and visually appealing structures.

Jewelry and Gemology: In the jewelry industry, even the slightest difference in measurements can significantly impact the value and aesthetics of a piece. Vernier calipers help jewelers and gemologists measure gemstones, diamonds, and jewelry components with exceptional accuracy.

DIY Projects and Home Use: Vernier calipers are not limited to professionals; they can also be valuable tools for DIY enthusiasts and home use. From measuring wood for carpentry projects to ensuring the right fit for household repairs, these calipers prove handy for various tasks.

Tips for Mastering Vernier Calipers

Mastering the art of using vernier calipers requires practice, precision, and attention to detail. Here are some valuable tips to enhance your proficiency in using these precision instruments:

a) Familiarize Yourself with the Scales: Before you start using vernier calipers, take some time to familiarize yourself with the main scale and vernier scale readings. Understand the divisions on each scale and how they correspond to measurements. This foundational knowledge will help you interpret the readings accurately.

b) Ensure Proper Zero Alignment: To achieve accurate measurements, it is essential to ensure that the zero point on the main scale aligns perfectly with the zero point on the vernier scale when the jaws are closed. Check and adjust the alignment if necessary before taking measurements.

c) Practice Steady Hands and Smooth Movements: The precision of vernier calipers demands steady hands and smooth movements. Avoid shaky hands that could lead to incorrect readings. Steady the caliper against a stable surface or use a clamp when measuring delicate objects.

d) Measure at the Right Temperature: Vernier calipers are sensitive to temperature changes, which can affect their accuracy. Whenever possible, measure objects at a stable room temperature to minimize potential errors.

e) Take Multiple Measurements: For critical measurements, it is advisable to take multiple readings and calculate the average to reduce the likelihood of errors. Repeated measurements help identify any inconsistencies and ensure reliable results.

f) Check for Parallax Error: Parallax error can occur when the eye is not perpendicular to the scale, leading to inaccurate readings. Always ensure that your line of sight is directly above the measurement being taken to avoid this error.

Vernier Calipers vs. Digital Calipers

The evolution of measuring instruments has introduced digital calipers as an alternative to traditional vernier calipers. Here’s a comparison between the two types:

a) Traditional Vernier Calipers:

Advantages::

- Simple and reliable design with no need for batteries or power source.

- High precision and accuracy for experienced users.

- Cost-effective compared to digital calipers.

Disadvantages::

- Require manual interpretation of scales, making them prone to human error.

- Not suitable for rapid and repetitive measurements.

b) Digital Calipers:

Advantages:

- Digital display for easy and quick readings, reducing the chances of misinterpretation.

- Some models offer additional features like data storage and conversion between units.

- Ideal for fast-paced environments with frequent measurements.

Disadvantages::

- Reliance on batteries or power source for operation, which might lead to downtime.

- Slightly higher cost compared to traditional vernier calipers.

- May not provide the same level of precision as experienced users using vernier calipers.

Ultimately, the choice between traditional vernier calipers and digital calipers depends on the user’s specific needs, preferences, and budget.

Troubleshooting and Common Errors

Despite the precision of vernier calipers, users may encounter certain challenges that can affect measurement accuracy. Here are some common troubleshooting tips:

a) Caliper Sticking or Jamming: If the caliper jaws are sticking or jamming during operation, clean them thoroughly to remove any debris or dirt. Lubricate the moving parts with a small amount of machine oil to ensure smooth movement.

b) Inconsistent Readings: Inconsistent readings may result from incorrect zero alignment or loose jaws. Double-check the zero position and ensure that the jaws are securely tightened to the object being measured.

c) Damage or Wear: Regularly inspect the caliper for any signs of damage or wear. Worn-out scales or damaged jaws can lead to inaccurate measurements. Replace any damaged parts promptly.

d) Battery Issues (for Digital Calipers): If using digital calipers, monitor the battery life and replace them as needed to prevent unexpected power loss during critical measurements.

Conclusion

In conclusion, mastering the use of vernier calipers is an invaluable skill in obtaining accurate measurements across various industries. The precise functioning of the upper and lower jaws is essential for achieving reliable results. By following the tips provided and understanding the comparison between traditional vernier calipers and digital calipers, users can select the most suitable tool for their measurement needs. Remember, consistent practice and attention to detail will pave the way to becoming a proficient user of these precision instruments, ensuring precision and excellence in every measurement task.